Thermographic Survey & Analysis

Thermographic Survey & Analysis

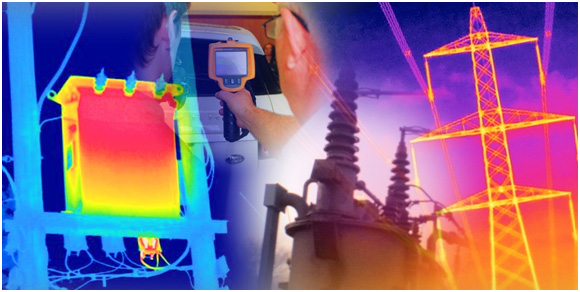

An Electrical thermal imaging survey is a non-evasive and non-destructive procedure using infrared technology. Thermal imaging can provide a cost effective, safe, non-intrusive and time saving testing technique for troubleshooting and preventative maintenance. If connections become loose this can create a resistance to current that can cause an increase in temperature. If left unchecked, heat can rise to a point where connections melt and break the circuit, which will cause system failures and lead to a potential fire risk. Besides loose connections, electrical systems can suffer from other common issues such as load imbalances and corrosion. Thermal imaging can quickly locate hot spots and problem areas where this may be occurring, so that the issue can be rectified before it becomes a major problem.Using infrared technology on electrical infrastructure is a renowned method of predictive maintenance and done correctly it can be effective at fault finding prior to equipment failure but it needs to be carried out correctly. Our strict protocols ensure that the faults we document are indeed items that require investigation and possibly remedial work and not simply loaded circuits manifesting temperature.

Benefits

This is a non-contact temperature measurement technology. The distinguishing benefits of this technology are detecting the abnormalities which might not get detected with normal electrical test equipment. This detection is in live condition without switching off the plant equipment. Only the survey area has to be directly accessible for capturing the thermal image without any barriers. The benefit of non-contact temperature measurement technology is the capability to inspect objects non-destructively and to make material conditions in deeper layers visible. The contact-free measurement of temperature distributions on objects or in processes constantly informs about the state of the object. Thus, deviations of the performance standard can be recognized. Thermal imaging can increase reliability and efficiency of your equipment, resulting in reduced failures and breakdowns and can significantly reduce maintenance costs and production losses. As a complementary test to the electrical periodic test and inspection, it can help to ensure the integrity and safety of your electrical systems and equipment. Thermal image surveys can be incorporated into your existing maintenance contract or be carried out as a one off test. While we are on site with the diagnostic tool you can also take advantage of this service to check other equipment that you may have concerns with, so please contact us to arrange a visit.

Applications

An electrical thermal imaging survey using a thermal imaging camera can be used for the thermal analysis of different types of equipment including Busbar systems, Distribution boards and fuse boards, High voltage systems, Transformers, Control panels, Batteries, UPS systems, Switchgears and switchboards etc.